Product Description

This item is in stock and ready for immediate shipping from our warehouse

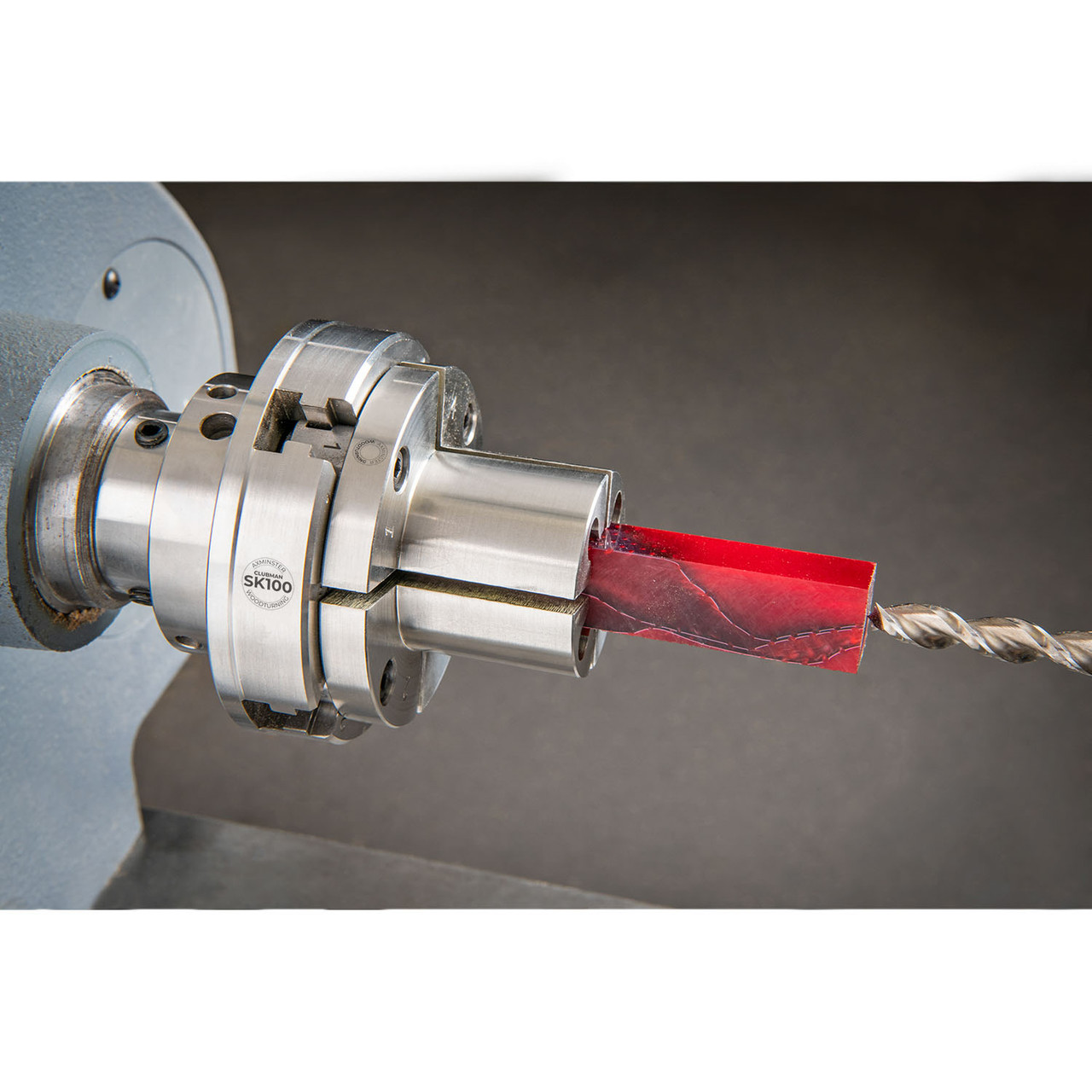

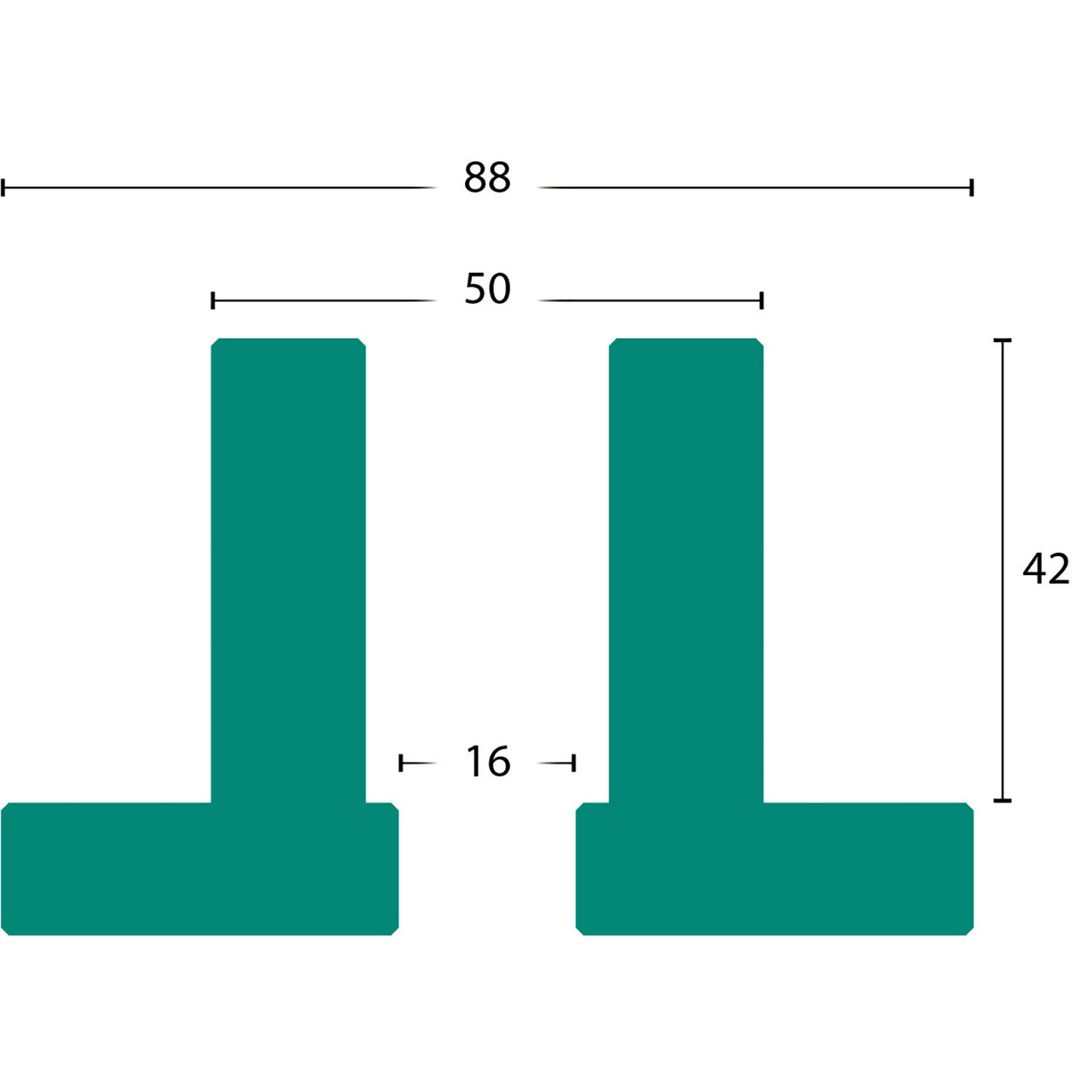

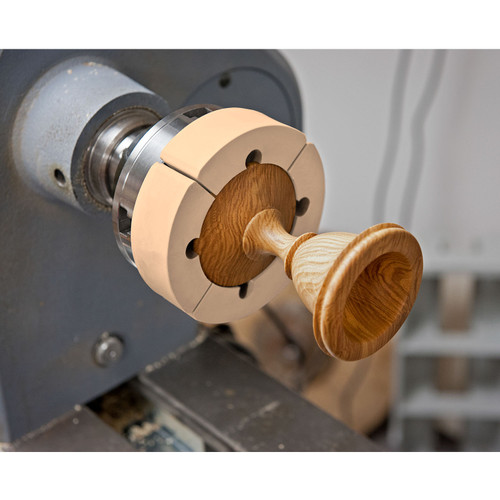

Drilling a pen blank can be tricky; the hole needs to be central, straight and round. While various jigs are available for doing the job on a Pillar drill, by far the best method is to do the job on the lathe. The Pen Jaws are 42mm (1 5/8") deep and can accommodate either round or square blanks from 16mm (5/8") upwards. The internal profile ensures a secure grip even if the pen blank is not quite square. Using the jaws in your chuck and mounted on your lathe ensures the blank and the drill bit are centred on the same axis. You also have control of the speed of rotation and the feed speed of the drill bit. Advance the bit steadily and retract frequently to clear the waste. Using the Pen Jaws you can drill blanks with confidence, knowing the result will be accurate and centred every time. Once fitted to your chuck you can drill batches of blanks to help speed up pen production. These pen jaws are suitable for the SK80, SK100 and SK114 chucks. (If fitting to the SK114 4 1/2" chuck, we recommend using the SK100 4" Accessory Mounting Jaws (106818) for this particular set of pen jaws).

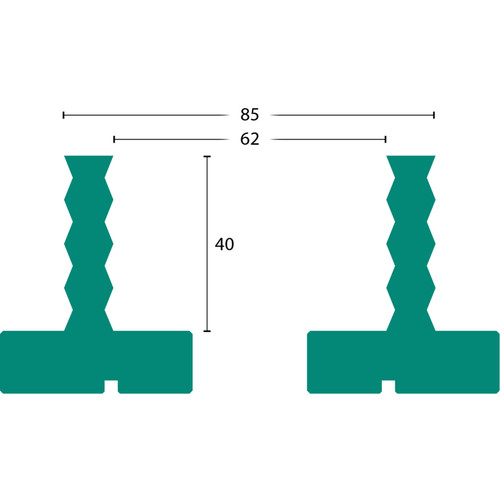

Features:- Potential gripping range: Round 16mm to 44mm (5/8" to 1 3/4")

- Potential gripping range: Square 16mm to 41mm (5/8" to 1 5/8")

- Recommended for SK80, SK100 and SK114 chucks

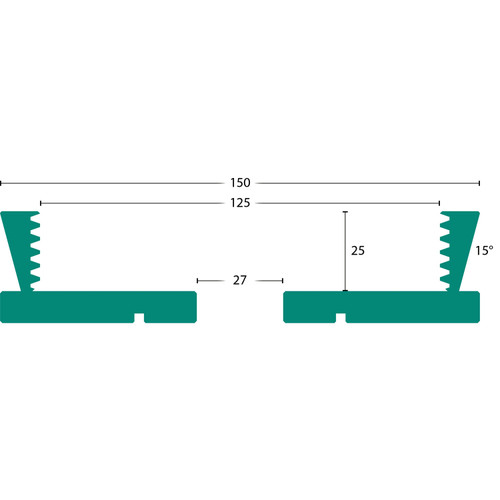

- Drawing dimensions taken when jaws form a true circle

- Highly accurate method of drilling pen blanks

- Drill bit and blank centred on same axis

- Made from stainless steel to protect against corrosion

- Made in Axminster, UK

- 1-year guarantee

- All sizes in inches are for reference only and are not as accurate as the sizes shown in millimeters. For best accuracy, please measure in millimeters.

- Check out the PRODUCT VIDEOS tab above to watch videos related to this product

- View our Axminster Chuck Jaws Comparison Page.

A range of super precision chucks and accessories, all uniquely designed and manufactured by those who truly understand woodturning. Precision-made in high grade stainless steel, the Chucks and their associated accessories have been developed over the years, to cover almost every situation likely to be encountered by the amateur or professional alike. In addition to chucks, Axminster Woodturning offers a Tailstock and Drive Centers, modular Tool Rests and Tools for Pen Making.

⚠ WARNING: Drilling, sawing, sanding or machining wood products can expose you to wood dust, a substance known to the State of California to cause cancer. Avoid inhaling wood dust or use a dust mask or other safeguards for personal protection. For more information go to http://www.P65Warnings.ca.gov/fact-sheets/wood-dust

022525Product Videos

Videos Hide Videos Show Videos

-

How To's - Work holding on the lathe with the Axminster Chuck System - Video 1

Holding your work correctly on the lathe is a crucial part of ...

-

How To's - Work holding on the lathe with the Axminster Chuck System - Video 2

Holding your work correctly on the lathe is a crucial part of ...

-

How To's - Work holding on the lathe with the Axminster Chuck System - Video 3

Holding your work correctly on the lathe is a crucial part of ...

-

Axminster SK114 Woodturning Chuck Package, The Woodturning Store

In this video, Steve Fulgoni gives an in-depth presentation of...

Custom Field

Product Reviews

3 Reviews Hide Reviews Show Reviews

-

Axminster pen jaws, AXM-103670

Easily installed on the SK100 chuck. Work fine for drilling my pen blanks. However, I found my One-Way chuck and jaws more accurate and easier to locate the center of my less-than-square blanks.

-

Pen jaw versatility

These are an exceptionally stable set jaws. Very solid, and beautifuly machined. They have a large amount of adjustment. I use them to drill center in 2" square blocks, then tap the hole to mount the blank on a threaded 1/4-20 screw chuck for turning. These are the most stable jaws I've found for this kind of process. I'm using them on an SK100 chuck.

-

Great product and Great Brand

I am a user of the Axminster chuck and jaw systems. I have both SK100 and SK114 chucks and tend to use the jaw sets interchangeably. The Pen Jaws are an excellent method of holding pen blanks and other similar wood blanks. I like the way that I can hold smaller objects for center hole drilling and turning. I was amazed at how many steps can be performed on the lathe for pen turning with a good set of jaws and the right process sequence. I definitely would recommend the Pen Jaws.